Universal tunnel drier "SL-01"

- Air inlet

- Air outlet

- Lid

- Air vent

- A group of heaters (3 x 8 kW)

- Insulation

- Air directing lids

- Air outlet

- Inlet cover

- Cart with wattles

Universal tunnel drier model "SL-01"

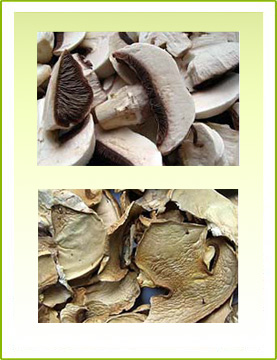

Universal tunnel drier model "SL-01" is primarily used for drying mushrooms, but it could also be used for drying all

sorts of fruit, vegetables, herbs and wild berries.

By replacing wattles (the wattles should be made of chrome), it would be possible to dry plums as well.

This type of drier uses electrical energy and has five heaters which are placed above the tunnel. The total power of the heaters is 24 kW (three groups of 8 kW), which are connected to a digital thermo regulator positioned at the middle of the tunnel and the purpose of which is to display current temperature in the tunnel at any moment. One group of heaters is directly connected to the thermo regulator which switches them off at a certain temperature (the programmed temperature).

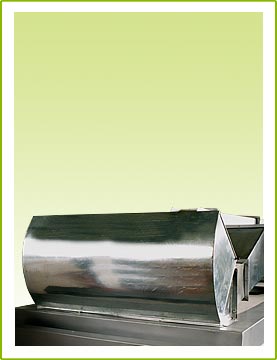

The drier is equipped with a power box (picture 2) where all the necessary elements are placed (bimetals, switches, fuses, etc.).

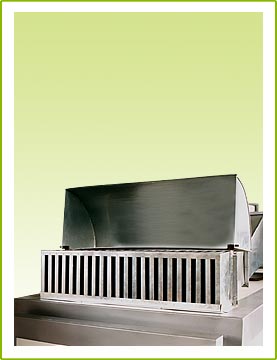

Radial vent (picture 1) pulls in cold air through the inlet of the heat inverter (1) and sends it on onto a group of heaters (5) where it takes over the heat and goes into the tunnel. Heated air goes through the tunnel, dries the produce and goes out into the atmosphere through the outlet of the heat inverter (2). If you want to use the same air, than you should close the lid (picture 4) at the air outlet of the inverter, this way directing the air into the tunnel again.

The drier has a drying capacity of approximately 150 kg of fresh mushrooms per round (it takes 6 h for a round), or 600 kg per day.

The drier is 3600 mm long, 1400 mm wide and 2100 mm high.

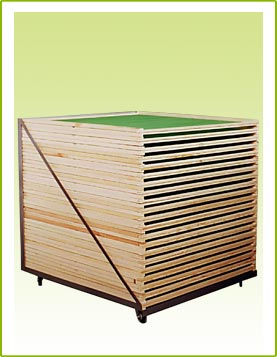

There are three carts with wattles inside the drier (the wattles are made of PVC), while the fourth one is used for preparation. There are 21 wattles in one cart (picture 5).

By replacing wattles (the wattles should be made of chrome), it would be possible to dry plums as well.

This type of drier uses electrical energy and has five heaters which are placed above the tunnel. The total power of the heaters is 24 kW (three groups of 8 kW), which are connected to a digital thermo regulator positioned at the middle of the tunnel and the purpose of which is to display current temperature in the tunnel at any moment. One group of heaters is directly connected to the thermo regulator which switches them off at a certain temperature (the programmed temperature).

The drier is equipped with a power box (picture 2) where all the necessary elements are placed (bimetals, switches, fuses, etc.).

Radial vent (picture 1) pulls in cold air through the inlet of the heat inverter (1) and sends it on onto a group of heaters (5) where it takes over the heat and goes into the tunnel. Heated air goes through the tunnel, dries the produce and goes out into the atmosphere through the outlet of the heat inverter (2). If you want to use the same air, than you should close the lid (picture 4) at the air outlet of the inverter, this way directing the air into the tunnel again.

The drier has a drying capacity of approximately 150 kg of fresh mushrooms per round (it takes 6 h for a round), or 600 kg per day.

The drier is 3600 mm long, 1400 mm wide and 2100 mm high.

There are three carts with wattles inside the drier (the wattles are made of PVC), while the fourth one is used for preparation. There are 21 wattles in one cart (picture 5).

The drier

General characteristics

| Capacity | 150 kg per round |

| Length | 3600 mm |

| Width | 1400mm |

| Height | 2100mm |